- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

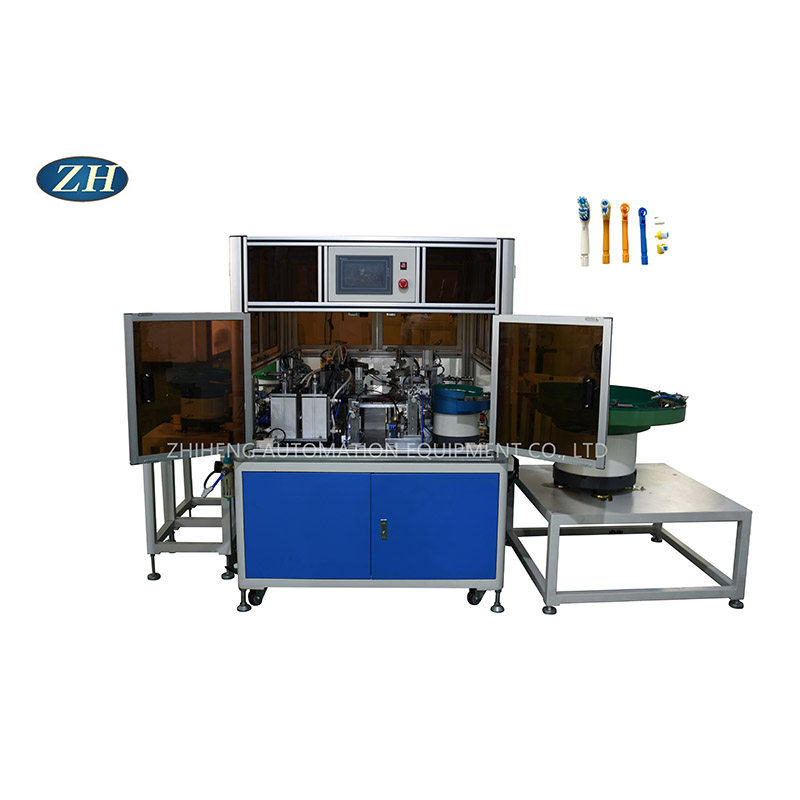

Automatic Zinc Shell Edge Milling And Tapping Machine Good Durability

Find a huge selection of Automatic Zinc Shell Edge Milling And Tapping Machine Good Durability from China at Yuyao Zhiheng.Automatic Zinc Shell Edge Milling And Tapping Machine Good Durability has a wide application prospect and important value in the field of metal processing. Users should pay attention to the brand, performance, durability testing and after-sales service of the equipment when purchasing, to ensure that the purchase of reliable quality and superior performance of the equipment.

Model:ZH-54

Send Inquiry

Introduction of Automatic Zinc Shell Edge Milling And Tapping Machine Good Durability:

As one of professional manufacturers, Yuyao Zhiheng would like to provide you high quality Automatic Zinc Shell Edge Milling And Tapping Machine Good Durability. And we will offer you the best after-sale service and timely delivery.Automatic Zinc Shell Edge Milling And Tapping Machine Good Durability can maintain its original performance and efficiency during long service life, thereby extending the service life of the equipment.Because the equipment has a high degree of stability and reliability, it can reduce production interruptions due to failure downtime, thereby improving production efficiency.Durable equipment can reduce the frequency of maintenance and replacement of parts, thus reducing production costs.Stable equipment performance can ensure that the processed zinc shell edge is smooth and smooth, and the tapping position is accurate, thereby improving product quality.

Parameter (Specification) of Automatic Zinc Shell Edge Milling And Tapping Machine Good Durability:

1. Automatic feeding zinc shell

2. Rotate and position the zinc shell

3. Milling the edge of the zinc shell contour

4. Mill the groove inside the zinc shell

5. Automatic moving zinc shell tapping station

6. Automatic tapping

7. Automatic punching

8. Automatic blanking (good and defective products blanking)

Specification,

Power supply:AC 220V /50HZ

Air pressure:above 0.6 MPa

Yield:1600-1800PCS/hour