- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

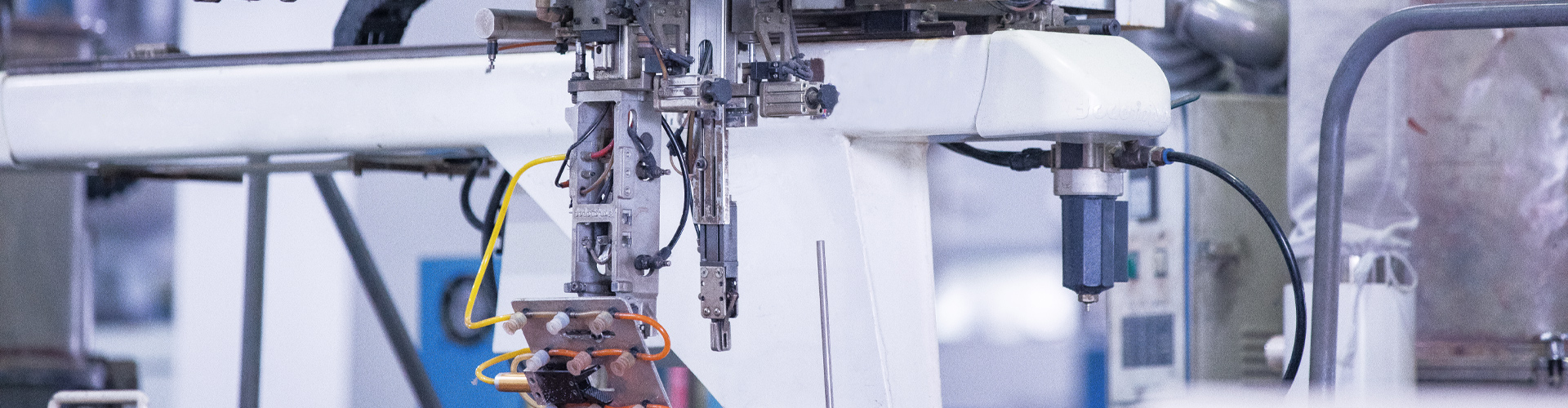

White Rod Sealing Ring Spring Assembly Machine Precision

One of the Chinese companies offering White Rod Sealing Ring Spring Assembly Machine Precision for wholesale is Yuyao Zhiheng. For you, we can offer better pricing and competent service. Should you be intrigued by White Rod Sealing Ring Spring Assembly Machine Precision, kindly get in touch with us. We adhere to the standard of conscience-driven, committed service at the cost of quality assurance.OneWe adhere to the standard of conscience-priced, devoted service, so you can feel secure.The stability of the seal ring spring assembly machine is very important for production efficiency and product quality. Stable machines ensure accuracy and consistency in the assembly process, reduce scrap rates and improve production efficiency. At the same time, stable machines can also reduce maintenance costs and extend the service life of equipment.

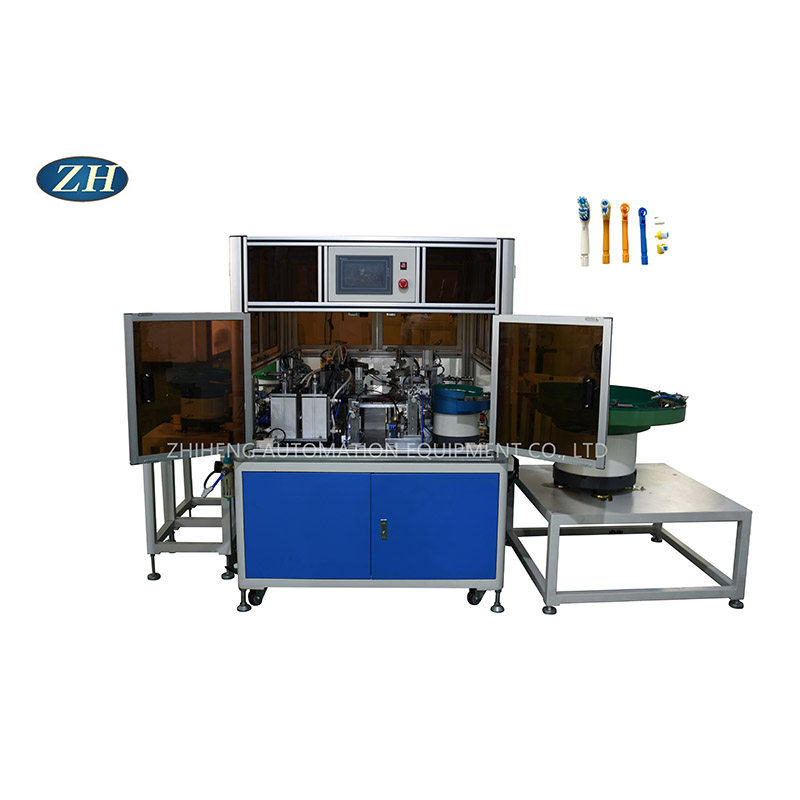

Model:ZH-40

Send Inquiry

Introduction of White Rod Sealing Ring Spring Assembly Machine Precision:

Find a huge selection of White Rod Sealing Ring Spring Assembly Machine Precision from China at Yuyao Zhiheng.A high-precision sealing ring spring assembly machine needs reasonable mechanical structure design, advanced control system, high-quality parts and good working environment control. At the same time, regular maintenance and maintenance as well as regular calibration and testing are also key to maintaining machine accuracy.The stability of the seal ring spring assembly machine is very important for production efficiency and product quality. Stable machines ensure accuracy and consistency in the assembly process, reduce scrap rates and improve production efficiency. At the same time, stable machines can also reduce maintenance costs and extend the service life of equipment.

Parameter (Specification) of White Rod Sealing Ring Spring Assembly Machine Precision:

1. Automatic feeding sealing ring

2. Automatic feeding stop collar

1. Automatic detection of stop collar

4.Automatic feeding spring

5.Automatic feeding white rod

6.Automatic press white rod

7.Automatic detection of spring and white rod

8.Automatic blanking of good and bad products

9.Automatic oiling of good products

Specification,

Power supply:AC 220V /50HZ

Air pressure:above 0.6 MPa

Yield:1600-1800PCS/hour